BMW

Digital Workplace Experience Design

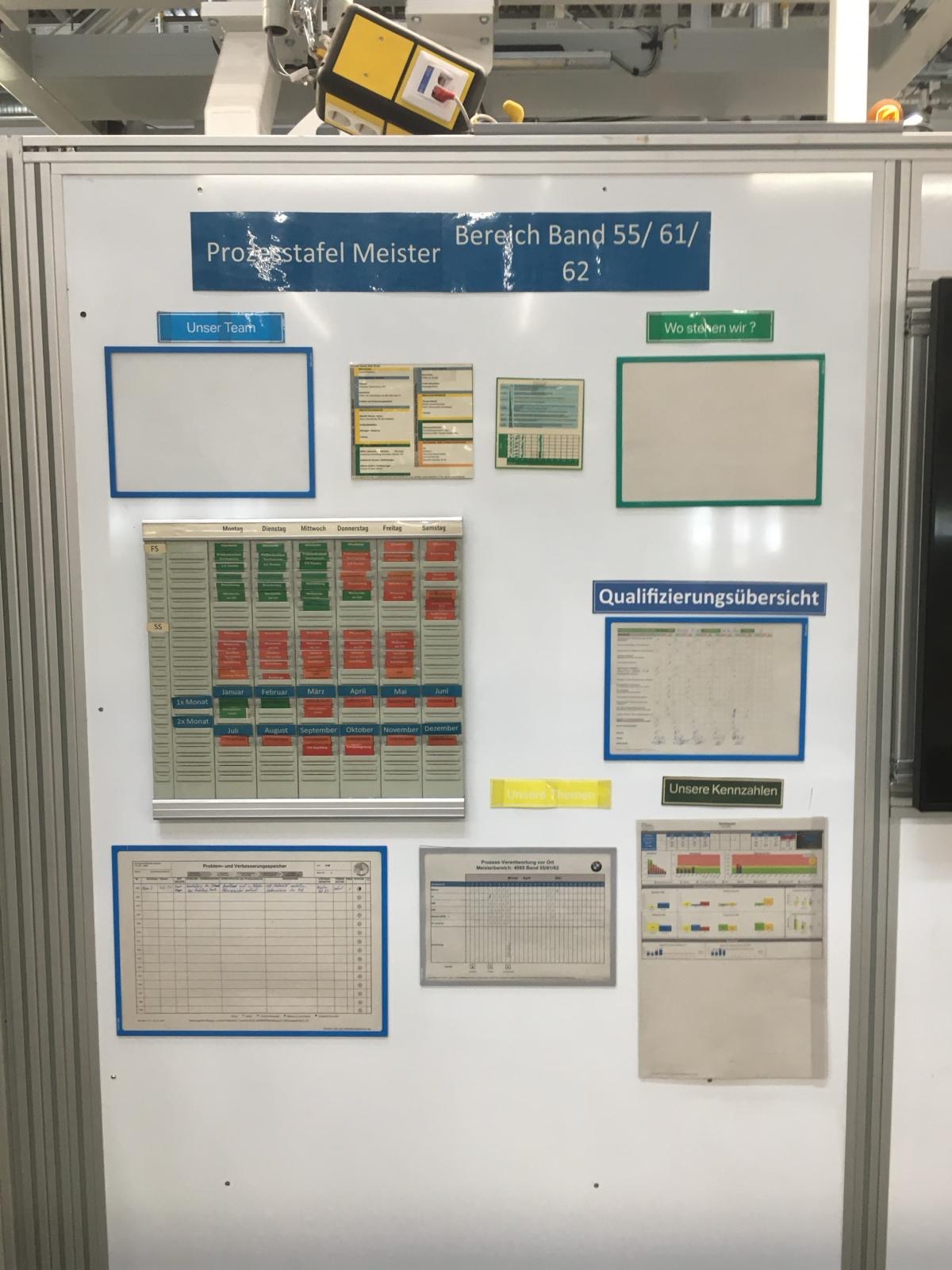

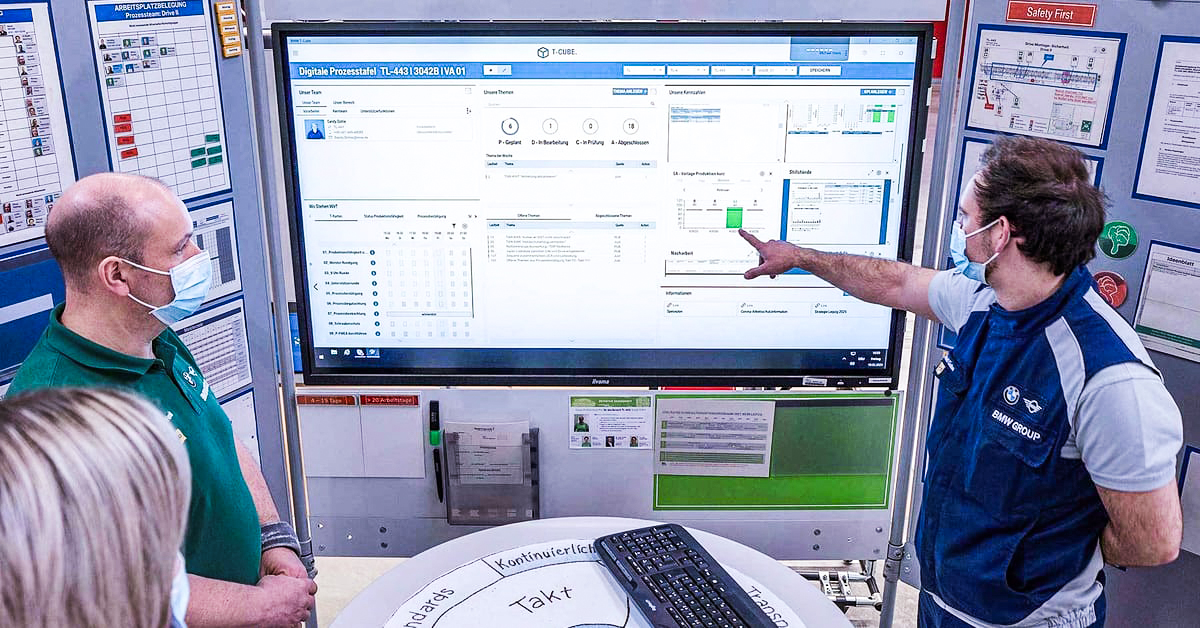

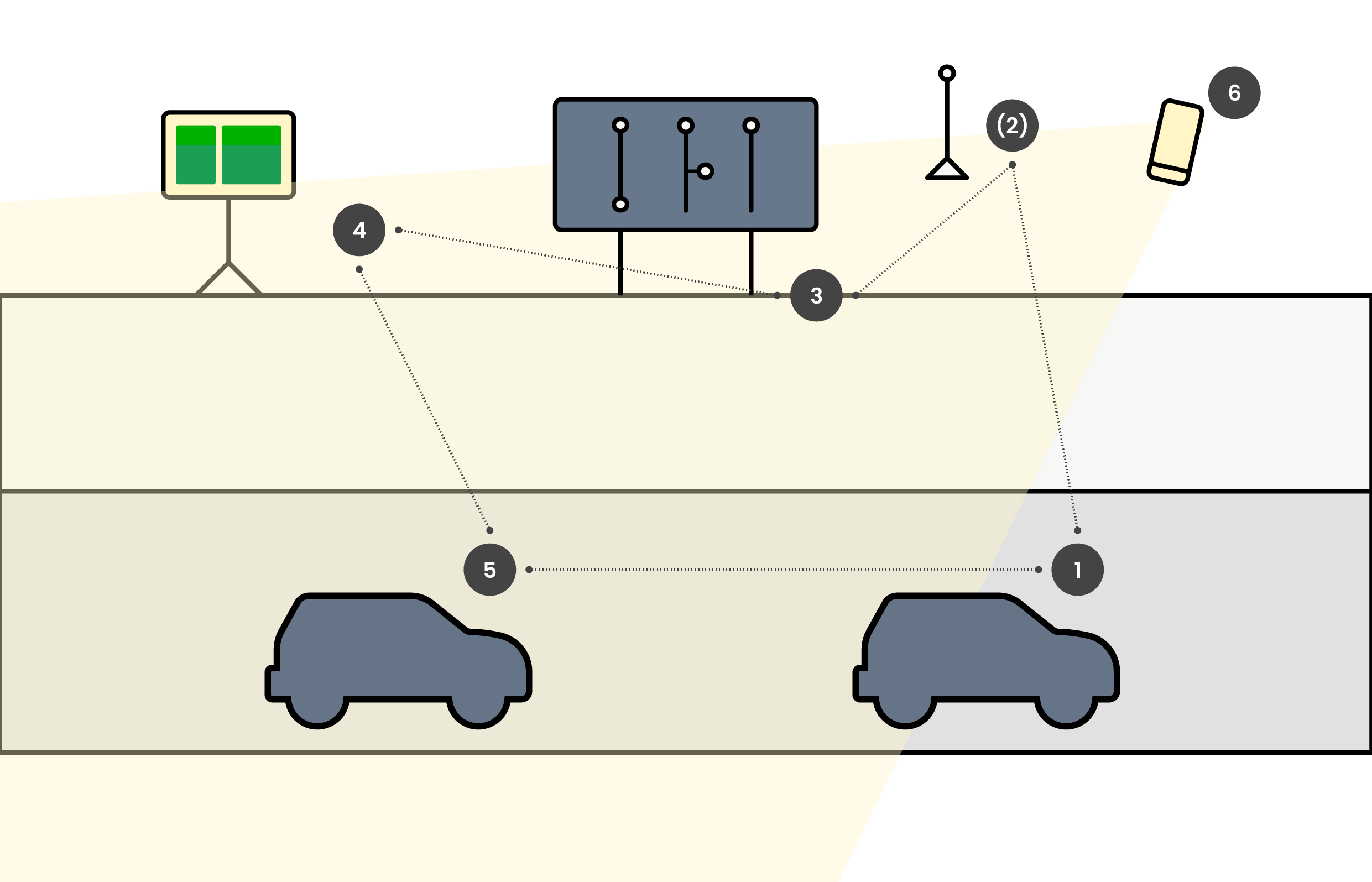

BMW’s production operations relied on analogue process boards that limited transparency, slowed information flow and reduced employee engagement. The project translated these physical coordination systems into a scalable digital solution designed to improve workflow clarity, operational efficiency and workforce adoption.

Inside the project

Goal

Design and prototype a digital process management system that increases operational transparency, reduces coordination errors, and supports workforce adoption during digital transformation.

Approach

Conducted contextual field research on the production floor to analyse workflows, information bottlenecks and coordination behaviours. Synthesised findings into user requirements and interaction principles, and developed iterative prototypes tested with line workers and supervisors. To support adoption, introduced engagement mechanics and clear visual hierarchies that translated familiar analogue rituals into intuitive digital interactions.

Impact

The digital solution improved workflow transparency and reduced coordination errors (internal evaluation ~80% usability improvement). The prototype served as a pilot initiative contributing to BMW’s broader digital transformation strategy in production environments.